Test Method: SATRA TM236

Breaking strength and tip deflection of needles

July 2000

SCOPE

This method is intended to determine the force required to break, and the maximum tip deflection prior to break, of a sewing machine needle. The method is applicable to all types of industrial sewing needles.

PRINCIPLE

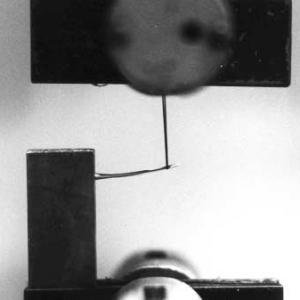

A needle is clamped in a jig in the bottom jaws of a tensile testing machine perpendicular to the direction of crosshead movement. A loop of thread is threaded through the eye of the needle and clamped in the top jaw of the tensile testing machine. The jaws are then separated until the needle breaks. The force at break, displacement of the tip and the type of damage that occurred are recorded.

REFERENCES

BS EN 10002-2:1992 - Verification of the force measuring system of the tensile testing machine.

HISTORY

First issued July 2000.

AVAILABILITY

This test method is available to members and non-members.

PRICE (ex. VAT)

This price is for a printed copy of the Test Method.

- Members: £84

- Non-members: £242

EN

EN ZH

ZH